Description

Features

- Robust stainless-steel construction, suitable for blending, mixing and reworking clay.

- Twin auger design

- Stainless auger shafts and blades.

- Zinc plated and powder coated base.

- Sealed for life ball bearings protected by “O” ring seals.

- Bucket feed hopper system for safe operation.

Specifications

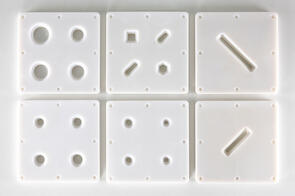

- Model: 80mm (3.1 inch) nozzle , 125mm barrel de-air pug mill

- Motor: Single phase 0.37kW 240v with integral thermal overload protection.

- Drive System: Industrial Gearbox

- Weight:

- Dimensions: (L)1180mm x (W)450mm x (H)650mm

- Blend dry scrap with multiple passes, just cut and pug into 100mm (4″) logs and re-feed. Blend/recycle approx 120kg/hr

(250lb/hr)

Innovative feed system. Clay is fed to the pug mill via a unique ‘bucket feeder’, eliminating the effort needed to pull a lever as with conventional pug mills.

A novel twin auger mixing chamber, containing two counter rotating augers, quickly draws the clay away from the feed area and thoroughly blends it within the large volume, stainless steel, mixing chamber.

The feeder completely removes the risk of injury caused by loading clay into the hopper, making the SUPER twin ideal for classroom as well as professional operation.

This system allows the pug mill to be left operating while the next piece of clay is being loaded. This removes the need for safety switches and other methods used by competing systems which cut power to the motor when the pug mill is being loaded –this crude approach creates unnecessary wear and strain on the drive train resulting in a reduced service life of the motor and gearbox.

This safe, easy loading feature is unique to the SUPER twin and creates a definite advantage over other pug mills.

All components, which come into contact with clay, are either stainless steel or plastic therefore eliminating any chances of clay contamination and staining even when using porcelains.