Description

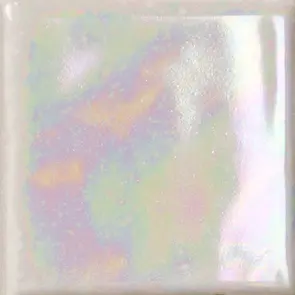

Laguna Clear Lowfire Dry Powder Glaze EM2020 Clear

Instructions for a basic Cone 05 Glaze Firing- Earthenware

Segment 1 10 degrees C per hour up to 100 degrees C

Glazed wares should be completely dry. It is advisable to glaze your work and allow it to dry overnight prior to loading and firing. Going 100 degrees per hour up to 200 allows any reaming moisture in the wares to evaporate/ dry.

This pace will also warm all the refractory materials (stilts, posts, and shelves) to a consistent temperature allowing all refractory materials to move together.

Segment 2 40 degrees C per hour up to 400 degrees C

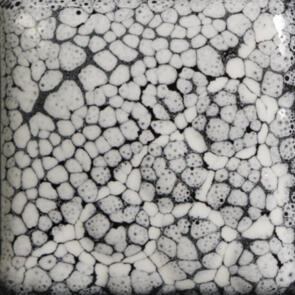

This allows time for the naturally occurring organics and gases in the clay to begin burning and or vapor out of the kiln. All clays contain organics and if not allowed adequate time to burn out, can get trapped and cause bloating of the clay or out gassing in later stages of firing that will show up in the form of pin holing in your glaze.

Segment 3 65 degrees C per hour up to 700 degrees C

This allows chemically combined water (on molecular level) found in all clay particulates, to dissipate/ dehydrate from the clay. In addition, it allows safe passage through the quartz inversion process.

This is one of the vital stages of the firing, both on the way up in heating and on the way down in cooling. During this time free silica found in all clays will expand by 1% while remaining particulates are shrinking; silica process reverse on the cooling cycle. You can imagine the contraction that is happening amongst all those clay particles. It is very stressful on the clay and going through this phase to quickly can cause damage in the form of cracks.

Segment 4 100 plus degrees C up to 1060 degrees C

Once you are past 1850 degrees F then most of the damage that can be done to clay has passed. Your clay is now considered "bisque" and has changed from clay to ceramic. Your bisque firing is now complete.

When firing is complete, shut down the kiln ensuring to seal it up the best you can to deter air drafting into the kiln. This includes turning off any vent system you may have. Allow the kiln to cool naturally. It takes the kiln approximately the same amount of time to cool as it did to bring it up to temperature. If your firing takes 13 hours to complete you can expect the cooling to take 13 hours.

It is of importance to proceed slowly through cristobalite inversion portion of the cooling. Cristobalite happens during cooling around 220 degrees C. During this time the silica that expanded earlier in the firing, now suddenly shrinks. Fast cooling at this temp can cause cracking.

Note: Some clay bodies are more susceptible to this process than others. It is always best to err on the side of caution.